High Guardrail Contruction Roll Forming Machine

- Product Details

- Company Profile

At any time online patiently answer a variety of customer questions, professional engineer team according to customer needs to do design and can provide overseas technical guidance services, the company's product categories of many brands have a long history of experience, rich quality strict control, long practical life of the machine, excellent quality, reasonable price . After-sales timely follow-up and engineering advice can be provided at any time. Our factory makes its own machine accessories, no need to purchase the cost reduction, and meet the safety export standards of the coupling pole. In many countries around the world, there are fixed large company customers of our factory to order many times, the most important thing is that our factory reputation is the first, seeking truth from facts.

Product Description

Main parameter

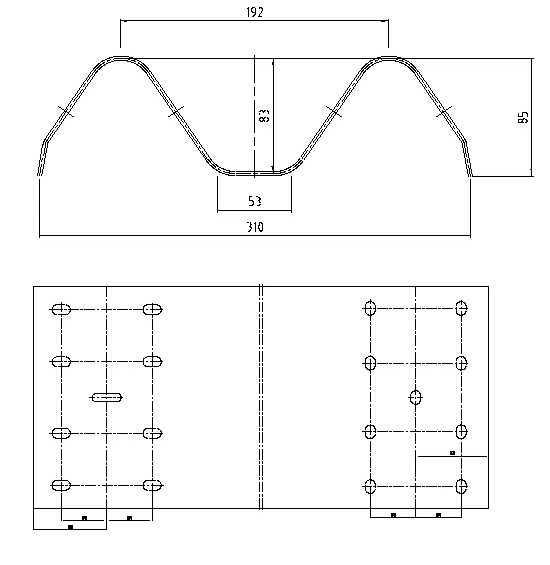

1. Specification of rolling material: Width: 480mm; Thickness:3-4mm; Q235A Galvanized steel sheet.

2. Working speed: 10 -12m/min

3. Roller steps: 13 pairs main rollers & 7 pairs flattening rollers

4. Material of roller: GCr15 bearing steel, quenched, HRC58°-62°

5. Material of main shaft: superior 45# steel, tempered.

6. Diameter of main shaft: ¢85 mm

7. Main motor power: 35 kw

8. Transmission:double-row chain drive

9. Structure of forming machine: wallboard

10. Flattening motor power: 2.2 kw

11. Hydraulic motor power: 11 kw, Pressure: 20 Mpa

12. Material of Punching and Cutting mould:Cr12

13. Cutting blade heat-treated.:HRC58°-62°

14. Punching and Cutting Way:Adopt hydraulic driving, flat panel punching, cutting after roll forming.

15. Electric control system: whole machine adopts PLC frequency control, Cut-to-length error≤±2mm

16. Machine dimension:13500mm×2700mm×1600mm

Equipment configuration

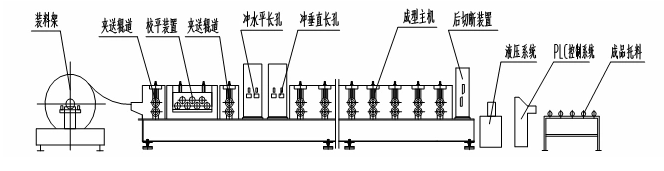

Manual Feeding device (3 T capacity), transmission, flattening device, before-punching device (2 sets), main machine and roller (including guide table), cutting (after roll forming) device, hydraulic system, electric control system, run out table, etc.

Production process

Manually uncoiling →Feeding & Correcting→ Seven rollers flattening device → Flat panel Punching→ Roll forming → Cutting after roll forming → Finished product.

Technological process figure

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier