Glazed Tile Steel Profile Roll Forming Machine

- Product Details

- Company Profile

t any time online patiently answer a variety of customer questions, professional engineer team according to customer needs to do design and can provide overseas technical guidance services, the company's product categories of many brands have a long history of experience, rich quality strict control, long practical life of the machine, excellent quality, reasonable price . After-sales timely follow-up and engineering advice can be provided at any time. Our factory makes its own machine accessories, no need to purchase the cost reduction, and meet the safety export standards of the coupling pole. In many countries around the world, there are fixed large company customers of our factory to order many times, the most important thing is that our factory reputation is the first, seeking truth from facts.

t any time online patiently answer a variety of customer questions, professional engineer team according to customer needs to do design and can provide overseas technical guidance services, the company's product categories of many brands have a long history of experience, rich quality strict control, long practical life of the machine, excellent quality, reasonable price . After-sales timely follow-up and engineering advice can be provided at any time. Our factory makes its own machine accessories, no need to purchase the cost reduction, and meet the safety export standards of the coupling pole. In many countries around the world, there are fixed large company customers of our factory to order many times, the most important thing is that our factory reputation is the first, seeking truth from facts.

Product Description

BH Glazed Tile Roll Forming Machine

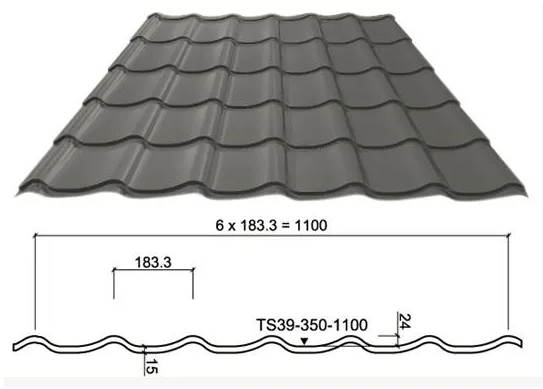

Profile drawing

Technical Parameter BH-24-183-1100

| Production Name | BH Glazed Tile Roll Forming Machine |

| Specification of Rolling Material | 1250×(0.4-0.8)×L,Yield Strength ≤250MPa |

| Working Speed | 12-15m/min |

| Roller Steps | 16 Steps |

| Frame of Machine | Welded with 350H Beam Steel |

| Thickness of Wallboard | 16mm |

| Roller Material | Adopts Superior 45# Forged Steel with Hard Chromium Plated |

| Shaft Material | Adopts Superior 45# Forged Steel Quenching and Tempering |

| Main Shaft Diameter | ¢70 mm |

| Main Motor Power | 5.5KW |

| Hydraulic Station Power | 4.0KW |

| Hydraulic Station Pressure | 8 -12MPa |

| Electric Control System | Adopts PLC |

| Machine Size | 7500x1700x1400mm |

Related Production

| Model | Feeding Width | Effective Width | Thickness Coil |

| BH-25.5-185-740 | 1000mm | 740mm | 0.3-0.8mm |

| BH-45-253-760 | 1000mm | 760mm | 0.3-0.8mm |

| BH-24-200-800 | 1000mm | 800mm | 0.3-0.8mm |

| BH-37-166-830 | 1250mm | 830mm | 0.3-0.8mm |

| BH-52-169-845 | 1000mm | 845mm | 0.3-0.8mm |

| BH-29-185-925 | 1000mm | 925mm | 0.3-0.8mm |

| BH-39-190-950 | 1000mm | 950mm | 0.3-0.8mm |

| BH-40-200-1000 | 1200mm | 1000mm | 0.3-0.8mm |

| BH-40-257-1028 | 1250mm | 1028mm | 0.3-0.8mm |

| BH-24-183-1100 | 1250mm | 1100mm | 0.3-0.8mm |

| BH-25-210-1122 | 1200mm | 1122mm | 0.3-0.8mm |

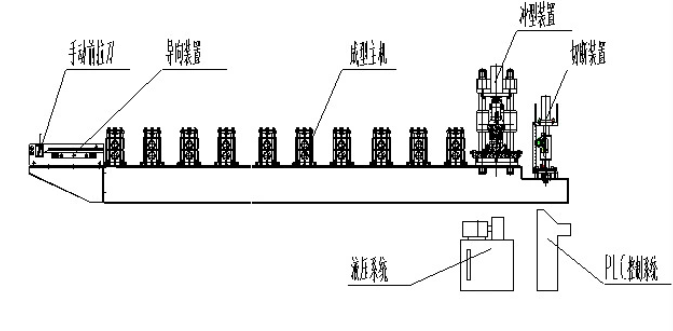

Machine Profile Drawing

Working Flow

Loading-----De-coiling & Feeding-----Adjusting & Guiding-----Roll Forming----- Punching after Roll Forming-----Cutting-----Run Our Table

Machine Photo

Our Company

Yingkou Bohai Machinery Equipment Manufature Co.,Ltd is professional manufacture of roll forming machine. We can provide design and instruct clients to do projects, offer technical support for clients, including project design, drawing supplied and engineer supplied.

Delivery

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier