Corrugated Sheet Roll Forming Machine

- Product Details

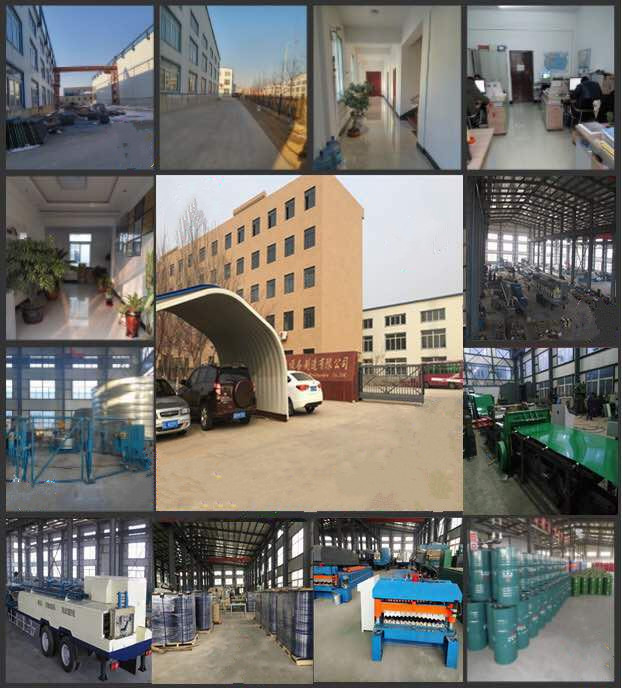

- Company Profile

At any time online patiently answer a variety of customer questions, professional engineer team according to customer needs to do design and can provide overseas technical guidance services, the company's product categories of many brands have a long history of experience, rich quality strict control, long practical life of the machine, excellent quality, reasonable price . After-sales timely follow-up and engineering advice can be provided at any time. Our factory makes its own machine accessories, no need to purchase the cost reduction, and meet the safety export standards of the coupling pole. In many countries around the world, there are fixed large company customers of our factory to order many times, the most important thing is that our factory reputation is the first, seeking truth from facts.

At any time online patiently answer a variety of customer questions, professional engineer team according to customer needs to do design and can provide overseas technical guidance services, the company's product categories of many brands have a long history of experience, rich quality strict control, long practical life of the machine, excellent quality, reasonable price . After-sales timely follow-up and engineering advice can be provided at any time. Our factory makes its own machine accessories, no need to purchase the cost reduction, and meet the safety export standards of the coupling pole. In many countries around the world, there are fixed large company customers of our factory to order many times, the most important thing is that our factory reputation is the first, seeking truth from facts.

Product Description

Main parameter

1. De-coiler: manual operation, passively de-coiling

2. Loading of de-coiler: 5 T

3. Frame of machine: welded with 350H beam steel

4. Guide feeding way of forming: side direction roller type

5. Forming machine type: wallboard and chain drive

6. Diameter of shaft: ¢76mm

7. Chain: 16A single row

8. Motor power of forming machine: 5.5KW

9. Line speed of forming machine: 5-17m/min

10. Steps of forming machine: 18

11. Roller material: superior 45# steel forging

12. Thickness of Chrome plated on roller: 0.05mm

13. Hydraulic station motor: 4 KW

14. Hydraulic station oil pump: gear pump

15. Cutting way: cut off after hydraulic shaped

16. Cutting blade material: Cr12

17. Cutting blade heat treatment: HRC58o-60

18. Rolling thickness: 0.4-0.8 mm

19. Feeding width: 1250mm

20. Precision of cut-to-length: ±2mm

21. Frequency changer : Panasonic

22. Computer adopts PLC : Panasonic

23. Dimension of machine: 8.5M x 1.6M x 0.8M

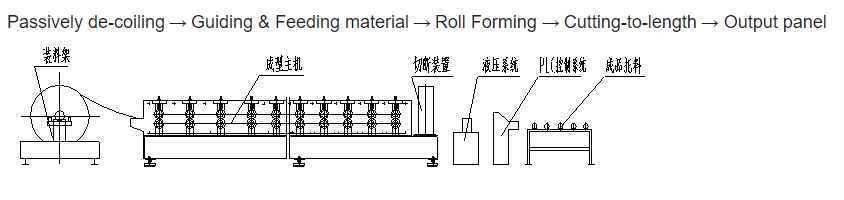

Technological process

Passively de-coiling → Guiding & Feeding material → Roll Forming → Cutting-to-length → Output panel

Equipment configuration

Normal manual De-coiler (5T); Main machine of roll forming; Hydraulic forming cutting; Hydraulic station; PLC computer operation cabinet; Run-out table

| No. | Item | Qty. |

| 1 | Passive de-coiler | 1 piece |

| 2 | Roll forming machine | 1 piece |

| 3 | Hydraulic cutting blade | 1 set |

| 4 | Hydraulic station | 1 piece |

| 5 | Computer control counter | 1 piece |

| 6 | Run out table | 3 pieces |

Project

Delivery

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier