Arch curving sheet roll forming machine

- Product Details

- Company Profile

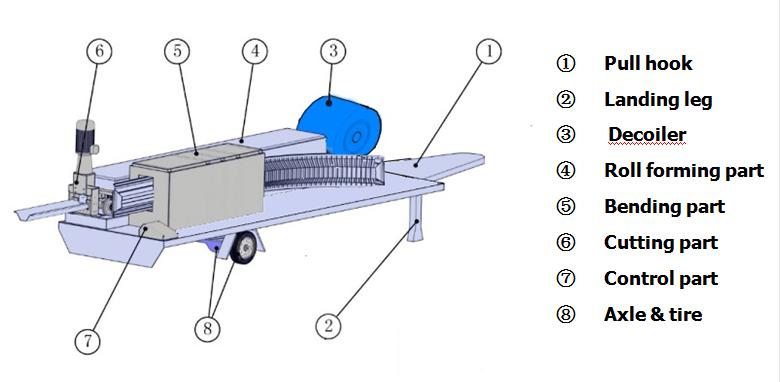

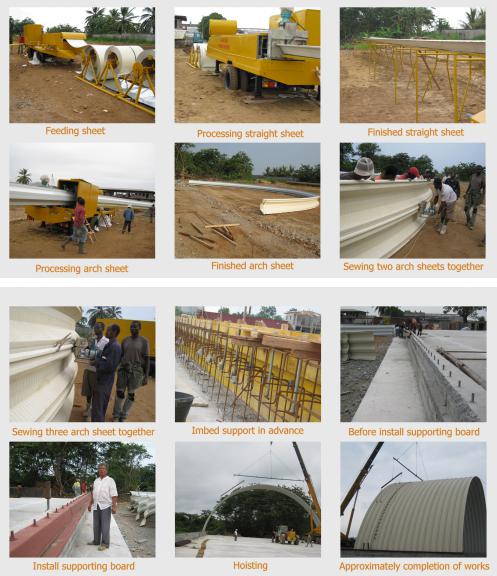

The machine can directly produce on work site, lower cost effectively. The project is widely used in mid-scale and small-scale construction, such as factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc. The machine designed on a trailer with the axles, our machine' axles are better than other supplier, ours is axles like car axles,quality is stronger,and live time is longer. It is not similar with the other suppliers' straight shaft.

Arch curving sheet roll forming machine

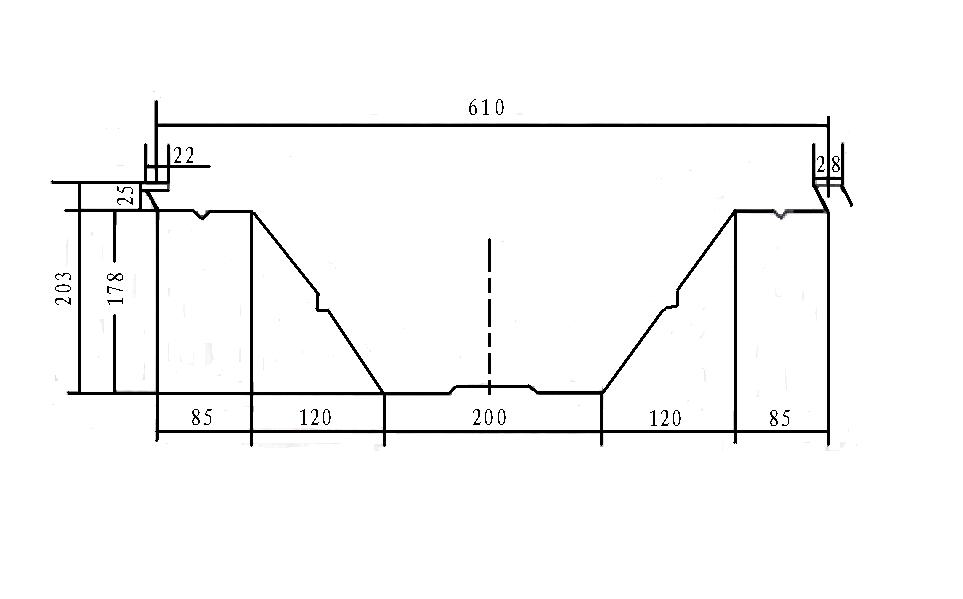

Technical Parameter of BH-914-610

Production Type | BH-914-610 |

Dimension | 11690mm X 2230mm X 2300mm (Double Axles & 8 Tires) |

Total Weight | About 10 Ton |

Feeding Width | 914mm |

Effective Width | 610mm |

Using Rate | 66.7% |

Thickness | 0.6-1.5mm |

Groove Depth | 243mm |

Bending Leaf | 10mm Thickness, Processed By CNC |

Cutting Blade | 12CrMov Material, Heat Treatment |

Cutting Type | Mechanical/Hydraulic Cutting |

Forming Type | Roll-Formed and Length-Set Cutting |

Controlling System | PLC |

Power | Total Motor Power : 17.5KW Roll Forming Main Motor Power : 7.5KW Bending Power : 3.0KW+1.5KWx2 Cutting Power : 4.0KW |

Seaming Power | 1.1KW+1.1KW |

Roller Material | 45# High-Quality Steel, Quenched HRC 55~65, Hard Chrome Plating |

Shaft Material | 45# High-Quality Steel, Galvanized |

Stand of Molding | 13+1 Steps |

Working Speed | Forming Part : 15m/min |

Suitable project | 6~38m |

De-Coiler | Inner-Diameter of Coil : 450mm ~ 650mm Load : 10Ton |

Equipment composition

Project pictures:

CCCME Member

CCCME Member 0

0 Chinese Supplier

Chinese Supplier